Fuel is one of the largest operating expenses for any commercial fleet—second only to payroll in many cases. With trucks consuming thousands of gallons of diesel annually, even a small improvement in fuel efficiency can lead to significant cost savings when scaled across an entire fleet. This makes fuel economy not just a financial lever but a strategic advantage in fleet management.

Moreover, fleets that prioritize fuel efficiency often experience fewer breakdowns, reduced maintenance costs, and improved driver satisfaction due to better-performing vehicles.

Rising Fuel Costs and Environmental Impact

Fuel prices are notoriously volatile, influenced by global markets, geopolitical tensions, and supply chain disruptions. As of recent years, spikes in diesel prices have created additional financial pressure on fleet operators. These costs are often unpredictable and can quickly erode profit margins—especially for long-haul and regional fleets.

Beyond cost, there’s increasing scrutiny on the environmental impact of transportation emissions. Diesel-powered trucks are significant contributors to greenhouse gas emissions, including CO₂ and NOₓ. With regulatory bodies tightening emissions standards and customers demanding more sustainable logistics partners, reducing fuel consumption has become an environmental imperative as well.

Improving fuel efficiency not only supports sustainability goals but also helps fleets stay ahead of compliance mandates from agencies like the EPA and FMCSA. Adopting greener, more efficient practices is no longer a “nice to have”—it’s a reputation-saving, regulation-meeting, and cost-cutting necessity.

Understanding the Key Factors That Affect Truck Fuel Consumption

Reducing fuel consumption starts with understanding what drives it. Fuel efficiency in trucks is influenced by a complex interplay of mechanical, environmental, and behavioral factors. Optimizing these variables can make a measurable difference in operating costs, vehicle performance, and emissions output. Below are the most critical factors:

1. Vehicle Weight and Load Distribution

The heavier the load, the more energy (and fuel) a truck needs to move. Overloaded trucks or improperly balanced cargo can strain engines, reduce fuel economy, and increase wear on tires and suspension systems.

- Best Practices:

- Use onboard scales to monitor load weight.

- Distribute cargo evenly to maintain proper axle balance.

- Avoid overloading to comply with DOT regulations and improve fuel performance.

- Consider lightweight materials and equipment to reduce tare weight.

- Use onboard scales to monitor load weight.

2. Aerodynamics and Drag

Aerodynamic resistance is a major fuel drain, especially at highway speeds. As speed increases, drag increases exponentially, making design and accessory choices critical for fuel efficiency.

- Key Considerations:

- Install aerodynamic devices such as side skirts, trailer tails, and roof fairings.

- Use cab extenders to reduce the gap between tractor and trailer.

- Keep windows and sun visors closed at highway speeds.

- Minimize external accessories that increase drag.

- Install aerodynamic devices such as side skirts, trailer tails, and roof fairings.

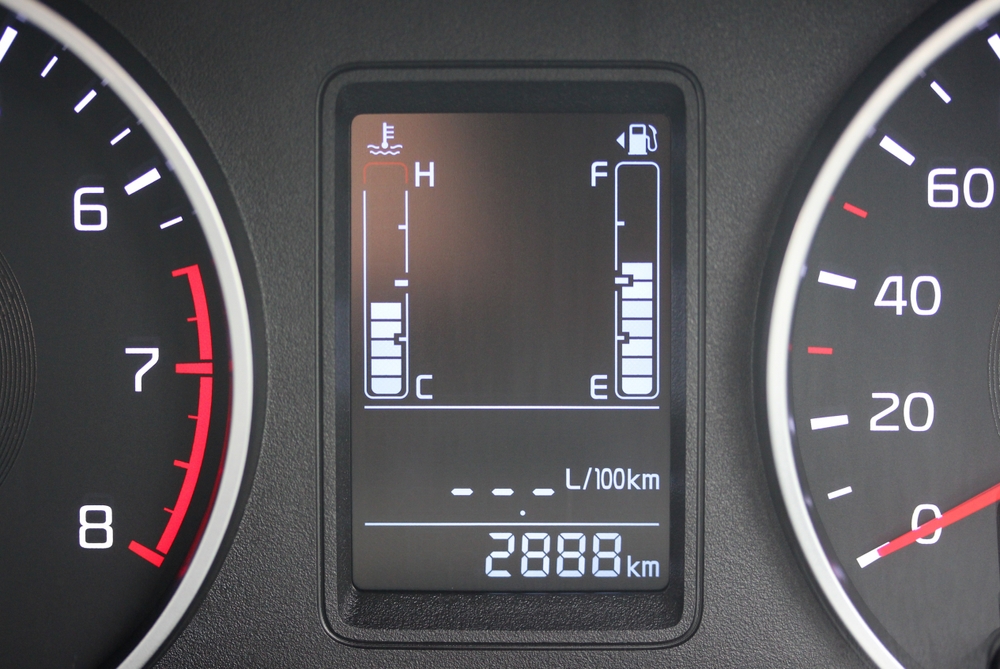

3. Engine Performance and Tire Pressure

A well-maintained engine and properly inflated tires play a foundational role in minimizing fuel waste. Neglecting routine checks can lead to inefficiencies, increased emissions, and higher fuel bills.

- Engine Optimization:

- Ensure regular oil changes, fuel filter replacements, and diagnostics.

- Monitor aftertreatment systems to prevent performance degradation.

- Use engine calibration updates from OEMs when available.

- Ensure regular oil changes, fuel filter replacements, and diagnostics.

- Tire Management:

- Under-inflated tires can reduce fuel economy by up to 1% per PSI below optimal pressure.

- Use automatic tire inflation systems or TPMS (Tire Pressure Monitoring Systems).

- Rotate and align tires regularly to prevent uneven wear and drag.

- Under-inflated tires can reduce fuel economy by up to 1% per PSI below optimal pressure.

4. Driving Behavior (Speeding, Idling, Aggressive Driving)

The driver is one of the most influential variables in fuel consumption. Poor driving habits can drastically reduce MPG, while trained, fuel-conscious drivers can improve it by 5–30%.

- Key Fuel-Wasting Behaviors:

- Speeding: Fuel efficiency drops significantly above 60 mph.

- Excessive idling: Burns 0.8 to 1 gallon of fuel per hour unnecessarily.

- Harsh acceleration and braking: Increases fuel usage and wear-and-tear.

- Speeding: Fuel efficiency drops significantly above 60 mph.

- Solutions:

- Implement driver training programs focused on fuel-efficient driving.

- Use telematics to monitor and coach driving behavior in real time.

- Set speed governors or use cruise control to maintain efficient speeds.

- Implement driver training programs focused on fuel-efficient driving.

5. Environmental and Route Conditions

External factors such as terrain, weather, and traffic can impact fuel economy in ways that are often overlooked.

- Terrain:

- Hilly or mountainous routes lead to higher fuel consumption due to frequent gear changes and increased engine load.

- Hilly or mountainous routes lead to higher fuel consumption due to frequent gear changes and increased engine load.

- Weather:

- Cold temperatures reduce engine and tire efficiency.

- Headwinds increase aerodynamic drag significantly.

- Cold temperatures reduce engine and tire efficiency.

- Traffic Conditions:

- Frequent stops, congestion, and detours increase idling and fuel burn.

- Frequent stops, congestion, and detours increase idling and fuel burn.

- Mitigation Strategies:

- Use route optimization software to select fuel-efficient paths.

- Monitor weather and traffic data in real-time to avoid high-burn conditions.

- Use auxiliary power units (APUs) or idle-reduction technology in extreme climates.

- Use route optimization software to select fuel-efficient paths.

Driver Behavior: The Front Line of Fuel Efficiency

When it comes to reducing fuel consumption in trucks, no factor is more immediate or impactful than driver behavior. Even the most fuel-efficient vehicle will underperform if operated inefficiently. Drivers are on the front lines of every fuel-saving initiative, and empowering them with knowledge, tools, and motivation is essential to maximizing MPG and reducing operational costs.

Training for Fuel-Efficient Driving

Fuel-efficient driving isn’t always intuitive—it requires specific habits and awareness that must be taught, practiced, and reinforced. A robust training program focused on eco-driving techniques can yield a 10–25% improvement in fuel economy.

Smooth Acceleration and Braking

- Sudden stops and hard accelerations cause fuel burn to spike and lead to excessive wear on brake systems and tires.

- Encourage drivers to anticipate traffic flow, maintain safe following distances, and operate with a “coast when possible” mindset.

- Train drivers to avoid “jackrabbit” starts and use gradual throttle inputs to maintain steady vehicle speed.

Optimal Gear Shifting

- Shifting too early or too late can drop engine efficiency and increase fuel consumption.

- Use engine RPM as a guide for ideal shift points—many modern trucks have shift indicators or automated transmissions that help.

- In manual transmission vehicles, drivers should be trained to operate in the engine’s most fuel-efficient RPM band.

Reducing Idle Time

- Unnecessary idling wastes approximately 0.8 to 1 gallon of fuel per hour and contributes to engine wear.

- Educate drivers on the cost of idling and enforce company-wide anti-idling policies.

- Equip trucks with idle reduction technology like Auxiliary Power Units (APUs), bunk heaters, or automatic engine shutdown features where applicable.

Behavior Monitoring Tools

Technology plays a critical role in helping both drivers and fleet managers understand and improve driving habits. Real-time feedback and long-term trend analysis are key to sustaining progress.

Telematics

- Telematics systems collect data on fuel use, acceleration, braking, idling, speed, and more.

- These systems help identify patterns of inefficiency across drivers, vehicles, and routes.

- Use dashboards and scorecards to provide clear, data-backed feedback to drivers during performance reviews.

In-Cab Coaching Systems

- Real-time in-cab coaching devices give drivers immediate audio or visual alerts when inefficient behaviors occur (e.g., harsh braking, over-revving, prolonged idling).

- These systems reinforce training on the road, helping drivers self-correct without waiting for post-trip reports.

- Some solutions integrate with gamification tools to reward immediate improvements.

Driver Incentive Programs

Motivating drivers to consistently apply fuel-efficient techniques is easier when there are incentives tied to performance. A well-designed incentive program promotes a positive, competitive culture and leads to sustainable fuel savings.

Gamification of Fuel Savings

- Use leaderboards, challenges, and achievements to make fuel efficiency engaging.

- Weekly or monthly contests can focus on highest MPG improvement, least idling hours, or best driving score.

- Publicly recognizing winners fosters healthy competition and builds morale.

Recognition for Low Fuel Usage

- Offer tangible rewards such as bonuses, gift cards, or extra time off for drivers who consistently meet or exceed fuel-efficiency benchmarks.

- Celebrate success stories in company newsletters or meetings to highlight the importance of driver contributions to fleet sustainability.

- Incorporate fuel performance into annual reviews or career development paths to reinforce its value.

By focusing on training, real-time coaching, and structured motivation, fleets can transform driver behavior from a variable expense into a controllable asset. With the right support, drivers become champions of fuel efficiency—and in turn, the company benefits from reduced costs, lower emissions, and improved operational performance.

Leveraging Technology to Reduce Fuel Consumption

Technology has become a cornerstone of modern fleet efficiency. From real-time telematics to intelligent routing and fuel analytics, fleets now have powerful digital tools to monitor, analyze, and optimize every mile driven. When used effectively, these technologies can significantly reduce fuel consumption, lower emissions, and enhance overall operational control.

1. Telematics Systems

Telematics systems collect and transmit data from the vehicle to fleet managers in real-time. These platforms are foundational to any fuel-reduction strategy because they offer deep visibility into driver behavior, vehicle performance, and route conditions.

Real-Time Data Tracking

- Miles Per Gallon (MPG): Monitor actual fuel efficiency by trip, route, and driver.

- Idling Time: Identify unnecessary idling periods to address waste and enforce idling policies.

- Harsh Driving Events: Track acceleration, braking, cornering, and speeding—behaviors directly linked to fuel waste and safety risks.

Integration with Maintenance and Routing

- Combine telematics data with maintenance software to detect fuel-related issues like underinflated tires, misfires, or clogged filters before they reduce efficiency.

- Integrate with routing platforms to adjust paths based on real-time vehicle health, road conditions, or fuel efficiency performance.

2. Route Optimization Software

Efficient routing is one of the most powerful ways to save fuel—especially for fleets with frequent stops, regional deliveries, or unpredictable traffic conditions.

Avoiding Traffic, Elevation, and Unnecessary Stops

- Advanced algorithms analyze real-time traffic data, road elevation profiles, weather conditions, and historical patterns.

- Drivers can be routed away from congestion zones, steep gradients, and areas with frequent stops—factors that increase fuel burn.

- Integration with customer delivery windows helps avoid waiting/idling time upon arrival.

Predictive Routing for Efficiency

- AI-powered platforms forecast fuel usage based on route complexity, terrain, and driving history.

- Predictive systems continuously adjust routes based on live conditions and driver feedback to maintain optimal MPG.

- These tools also allow dispatchers to assign jobs to the most fuel-efficient vehicles for a given trip profile.

Putting It All Together

By integrating telematics, routing tools, and fuel management platforms, fleets can create a data-driven fuel efficiency strategy. These technologies not only help fleets monitor and reduce fuel usage in real time, but they also support long-term planning, predictive maintenance, and driver accountability.

Fleets that embrace these systems consistently report up to 15–25% fuel savings, reduced emissions and compliance risk, improved driver performance, and tighter control over operating expenses.