Fleet safety management is crucial for organizations that depend on vehicles for their operations, whether commercial trucking, public transportation, delivery services, or any other vehicle-reliant activity. Effective fleet safety management protects employees, minimizes financial risks, preserves company reputation, and ensures operational continuity. Vehicle-related accidents and incidents carry significant costs, including legal liabilities, increased insurance premiums, regulatory penalties, repair expenses, and potential downtime. Beyond financial implications, effective fleet safety management also safeguards public safety, enhances driver retention by promoting a safer work environment, and reinforces positive corporate responsibility.

Fleet Risk Assessment is a systematic process used to identify, evaluate, and mitigate risks associated with fleet operations. It involves thoroughly examining vehicle safety conditions, driver behaviors, operational practices, and environmental factors to determine the likelihood and potential impact of accidents or regulatory violations.

Conducting regular fleet risk assessments is significant because it allows fleet managers to proactively recognize and address vulnerabilities before they escalate into costly or dangerous incidents. An effective risk assessment supports data-driven decisions, ensures compliance with regulations such as FMCSA and DOT guidelines, and enhances overall safety performance. Ultimately, comprehensive fleet risk assessment reduces liability exposure, protects company assets, and promotes a safety-focused organizational culture.

Why Conduct Fleet Risk Assessments?

Fleet risk assessments offer significant strategic benefits by proactively identifying risks that could negatively affect fleet operations. Here are key reasons why fleet risk assessments should be integral to fleet management:

A. Liability Concerns

Operating fleets inherently involves liability risks—accidents, injuries, and property damage can expose an organization to expensive litigation, settlements, and reputational damage. Fleet risk assessments help identify potential hazards, high-risk driving behaviors, or maintenance deficiencies, enabling fleet managers to take corrective action before incidents occur. This proactive approach significantly reduces liability exposure, protecting the organization’s finances, public reputation, and operational stability.

B. Regulatory Compliance (FMCSA, DOT)

Fleet operations are subject to strict regulatory oversight from authorities like the Federal Motor Carrier Safety Administration and the Department of Transportation. Fleet risk assessments ensure compliance by systematically evaluating driver qualifications, Hours-of-Service adherence, vehicle inspection and maintenance procedures, and documentation practices. By regularly assessing regulatory compliance, fleets avoid costly penalties, fines, out-of-service orders, and negative impacts on CSA (Compliance, Safety, Accountability) scores.

C. Cost Reduction (Insurance Premiums, Maintenance Costs)

Fleet operations carry significant direct and indirect costs associated with safety incidents and downtime. Comprehensive fleet risk assessments reduce financial burdens by pinpointing factors contributing to increased insurance premiums, such as frequent accidents or citations. Addressing these risk factors through targeted training, improved maintenance schedules, and safer operational practices can lead to lower insurance costs. Additionally, proactive maintenance planning driven by risk assessments reduces vehicle downtime, minimizes unexpected repair expenses, and maximizes fleet utilization and efficiency.

D. Enhancing Driver Safety and Retention

Drivers represent the frontline of fleet safety; their well-being directly impacts operational effectiveness and profitability. Regular fleet risk assessments identify areas of potential driver risk, including unsafe behaviors, fatigue, insufficient training, or inadequate adherence to safety policies. By addressing these issues proactively, fleets demonstrate a clear commitment to driver safety, fostering employee trust and loyalty. This focus on driver well-being not only reduces accidents but also improves morale, job satisfaction, and retention rates—critical factors for long-term operational stability and reduced recruitment costs.

Key Components of an Effective Fleet Risk Assessment

An effective Fleet Risk Assessment integrates multiple layers of evaluation, examining vehicles, drivers, and operational practices comprehensively to achieve a proactive safety approach.

A. Vehicle Assessments

1. Maintenance Schedules and Inspections

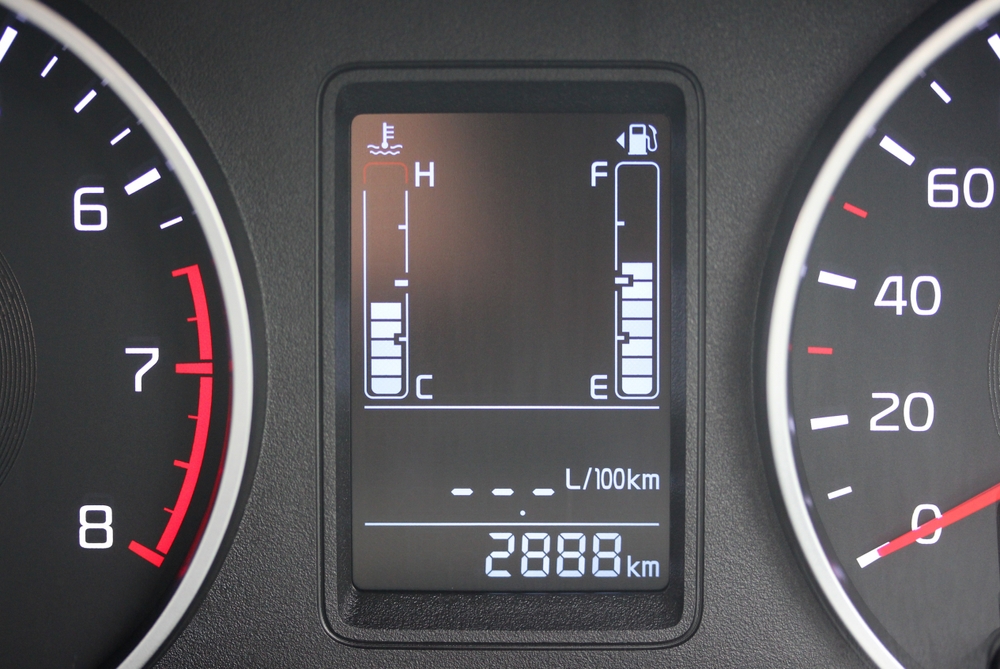

- Routine preventive maintenance schedules based on mileage, engine hours, or manufacturer guidelines.

- Regular vehicle inspections (daily pre-trip and post-trip inspections) to proactively identify issues.

- Documentation of inspections and repairs to ensure regulatory compliance and identify recurring problems early.

2. Vehicle Age and Condition Tracking

- Monitoring the age, mileage, and overall condition of each vehicle to predict maintenance needs and replacement schedules.

- Using analytics to determine the lifecycle of vehicles, ensuring aging vehicles do not become liabilities.

- Establishing clear criteria for replacement, balancing cost efficiency with safety and reliability.

B. Driver Assessments

1. Driver Qualification Files (DQFs)

- Maintaining comprehensive DQFs to ensure compliance with DOT and FMCSA regulations, including valid licenses, medical certificates, background checks, and training records.

- Regular audits and updates to DQFs to proactively identify compliance issues and prevent regulatory violations.

2. Driver Behavior Monitoring (Telematics Data, Dashcams)

- Leveraging telematics systems to track driver behaviors such as speeding, harsh braking, rapid acceleration, idling, and Hours-of-Service compliance.

- Utilizing dashcams and video analytics to review driving incidents, enhance coaching opportunities, and provide evidence in case of disputes.

- Real-time monitoring and alerts enabling immediate corrective actions to prevent accidents and unsafe driving practices.

3. Driver Safety Scores

- Developing and implementing driver safety scoring systems that aggregate data from multiple sources (telematics, dashcams, violation history).

- Using safety scores to identify high-risk drivers, tailor individualized coaching plans, and recognize high-performing drivers.

- Incorporating safety scores into incentive programs to foster a competitive yet safety-oriented culture among drivers.

C. Route and Operational Assessments

1. Route Optimization and Risk Evaluation

- Analyzing and optimizing routes to minimize driver exposure to known hazards, high-risk roadways, and challenging driving conditions.

- Assessing routes regularly for efficiency, ensuring drivers avoid congested areas, hazardous intersections, or regions prone to frequent accidents.

- Integrating advanced route planning software to dynamically respond to changing conditions and risks.

2. Hazard Identification (Weather, Road Conditions)

- Actively monitoring weather forecasts and road conditions to anticipate potential hazards and adjust routes accordingly.

- Providing drivers with timely and accurate hazard updates (road closures, severe weather alerts, construction zones) to mitigate risks proactively.

- Developing contingency plans to handle unforeseen route disruptions or adverse conditions, ensuring operational flexibility and driver safety.

Techniques for Performing Comprehensive Fleet Risk Assessments

Implementing a thorough fleet risk assessment requires using advanced techniques and systematic evaluations to proactively manage risks and enhance safety. Here are critical methods for performing effective and comprehensive fleet risk assessments:

A. Data-Driven Risk Analysis

1. Leveraging Telematics and Analytics

- Utilize telematics solutions to capture real-time vehicle and driver data, such as speed, braking patterns, acceleration, idling, and Hours-of-Service (HOS) compliance.

- Analyze this data to detect risky driving behaviors and vehicle performance issues, allowing timely intervention before incidents occur.

- Integrate analytics platforms to generate actionable insights, highlighting areas of increased risk or safety performance trends for continuous improvement.

2. Predictive Analytics for Risk Forecasting

- Apply predictive analytics tools to historical and real-time data to anticipate potential incidents or vehicle breakdowns.

- Forecast high-risk scenarios based on patterns in driving behavior, vehicle conditions, and external factors such as weather or road conditions.

- Establish risk scores and predictive models that inform targeted interventions, preventive maintenance, and proactive training initiatives.

B. Regular Audits and Compliance Checks

1. Regulatory Adherence

- Conduct periodic audits to ensure fleet operations comply fully with FMCSA and DOT regulations, including vehicle inspections, maintenance documentation, driver qualifications, and HOS regulations.

- Systematically verify compliance with state and federal laws, proactively identifying gaps or deficiencies and addressing them swiftly to avoid penalties and liabilities.

2. CSA Compliance Tracking

- Regularly monitor Compliance, Safety, Accountability (CSA) scores, analyzing areas like unsafe driving, hours-of-service violations, and maintenance-related compliance.

- Use CSA tracking as an integral part of the fleet risk assessment process, proactively addressing compliance deficiencies before they escalate into violations or penalties.

- Develop corrective action plans based on CSA data, improving both operational practices and driver training strategies.

C. Incident and Accident Analysis

1. Root Cause Analysis

- After an incident or accident occurs, implement thorough root cause analysis (RCA) processes to understand the underlying causes—not just symptoms—of safety issues.

- Analyze contributing factors across multiple dimensions, including driver behavior, vehicle condition, environmental conditions, and procedural gaps.

- Utilize RCA results to refine safety policies, enhance training programs, and improve operational procedures, significantly reducing the likelihood of future incidents.

2. Trend Identification and Mitigation

- Examine incident data to identify patterns, frequency, and severity of accidents or violations over time.

- Use trend analysis to uncover recurrent issues such as specific drivers engaging in risky behaviors, vehicle reliability problems, or problematic routes.

- Implement targeted mitigation strategies such as customized training programs, preventive vehicle maintenance protocols, or route optimization based on identified trends, effectively addressing potential risk areas before they result in incidents.

Integrating Technology into Fleet Risk Assessments

Leveraging technology is essential for conducting robust fleet risk assessments. Modern fleet safety solutions significantly enhance visibility into driver behavior, vehicle conditions, and operational risks, leading to more proactive management and informed decision-making. Below are key technologies fleets can integrate to elevate their risk assessment practices:

A. Telematics Systems

- Real-time Vehicle and Driver Monitoring: Telematics systems continuously collect data on speed, location, braking intensity, acceleration patterns, idling duration, fuel consumption, and Hours-of-Service (HOS) compliance.

- Behavior Analysis and Risk Detection: Analyzing telematics data enables fleet managers to identify unsafe driving behaviors (e.g., speeding, harsh braking, aggressive acceleration) and proactively coach drivers before incidents occur.

- Preventive Maintenance Alerts: Telematics platforms detect vehicle performance anomalies, allowing fleets to schedule proactive maintenance and avoid unexpected breakdowns or incidents caused by equipment failure.

B. Dashcams and Video-Based Safety Solutions

- Incident Capture and Documentation: Dashcams record real-time footage of driving conditions and incidents, providing concrete evidence to accurately assess and understand collision circumstances or near-misses.

- Enhanced Coaching Opportunities: Video-based solutions allow fleet managers to review actual driving behaviors with drivers, enabling targeted, personalized coaching to correct unsafe habits effectively.

- Liability Protection and Claims Reduction: Dashcam footage helps exonerate drivers from false claims, reducing fleet liability exposure and related legal expenses, while reinforcing a culture of accountability.

C. Advanced Driver Assistance Systems (ADAS)

- Collision Avoidance Technologies: ADAS includes features such as forward collision warnings, lane departure alerts, automatic emergency braking, adaptive cruise control, and blind-spot detection. These technologies actively assist drivers in avoiding accidents or mitigating collision severity.

- Driver Fatigue and Distraction Monitoring: Certain ADAS platforms can detect and alert drivers to fatigue, distraction, or inattentiveness, significantly reducing risk from these common safety hazards.

- Data Integration for Enhanced Risk Profiles: Integrating ADAS data with fleet management software provides valuable insights into driver behavior trends and vehicle safety performance, further refining fleet risk assessments.

D. AI-Driven Predictive Safety Platforms

- Predictive Risk Modeling: AI-driven systems analyze historical telematics data, accident reports, and environmental factors to anticipate potential risks, such as vehicle failures or accident-prone drivers and routes.

- Proactive Interventions and Recommendations: Predictive platforms offer real-time recommendations, enabling fleet managers to intervene early by providing targeted driver training, adjusting routes, or scheduling preventive vehicle maintenance.

- Continuous Improvement of Fleet Safety Programs: Using machine learning and AI algorithms, these platforms continuously refine their predictive accuracy over time, allowing fleets to implement increasingly effective, data-informed safety interventions and reduce overall risk exposure.

Take the next step in fleet safety management. Discover how Fleetworthy can empower your fleet to reduce liability, enhance compliance, improve driver retention, and achieve greater operational efficiency. Contact us today!